- Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

- Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

V Bottom Paper Bag Machine With Color Printing Online

Product Description

V Bottom Paper Bag Machine With 2 Colors Printing Inline can use the primary color paper roll as raw material to produce the v bottom paper bags with logos directly due to the 2 colors printing unit inline. Also if the paper bags are not necessary with the logo, the printing unit also can stop, it is easy to operate. The machine controlled by servo motor and adjust the length in the touch screen directly. It is an ideal equipment for the begin of customers to invest the paper bag business because the high cost performance and quick return.

Machine Parameters

|

Model |

JD-400 |

JD-650 |

|

Paper Roll Width(mm) |

220-720 |

220-960 |

|

Width of bag(mm) |

80-240 |

80-350 |

|

Length of bag (mm) |

120-420 |

220-750 |

|

Paper Grams (g/m²) |

30-80 |

30-80 |

|

Speed (pcs/min) |

60-400 |

60-400 |

|

Total Power (kw) |

6 |

8 |

|

Machine Weight (kg) |

1450 |

3500 |

|

Machine Size (mm) |

4400*1700*1600 |

5500*2100*1800 |

Technical Parameter of 2/4 colors printing machine

| Model of Machine | YT-800 Flexo Printing Machine (2 4 colors) |

| Max.Width of Printing Material | 800mm |

| Max.Printing Width | 760mm |

| Length Range of Printed | 191-914mm |

| Printing Speed | 80m/min |

| Thickness of Plate (Including double-sided tape) | 2.38mm |

| Total Power | 10kw |

| Machine Weight | 200kg |

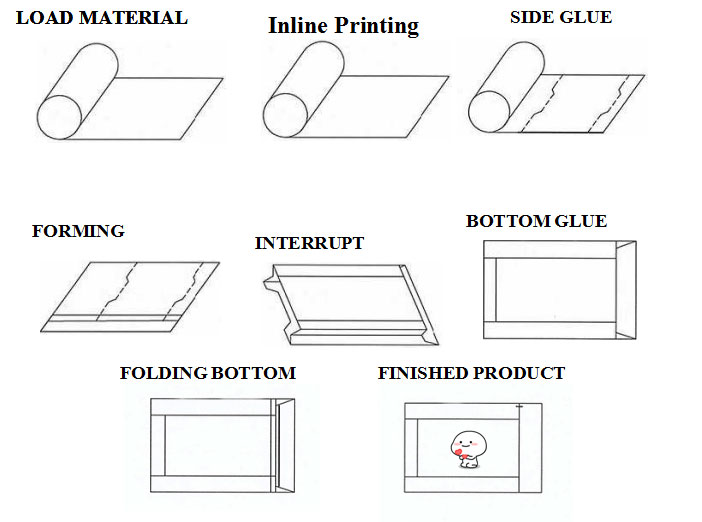

Producing Process

Samples

This machine is used for primary color paper or printed web paper. It is used to make paper bags with pointed bottom at one time.

The machine can be used in various paper bags with high speed and efficiency. It is an ideal equipment for paper bag production.

This machine is composed of drum feeding (hydraulic feeding, automatic deviation correction, tension adjustment), side gluing,printing paper electric eye tracking,base paper into cylinder, fixed-length drawing cutting, bag bottom indentation opening, bag bottom gluing forming, bag out finishing and so on.

The whole machine is controlled centrally by PLC touch screen and servo motor controls the length of paper bag.A sachet bag is a small, flexible, sealed bag that can be used to package both dry and liquid products. Sachets can be made from a variety of materials, including kraft paper and recycled and recyclable plastic.