- Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

-

Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

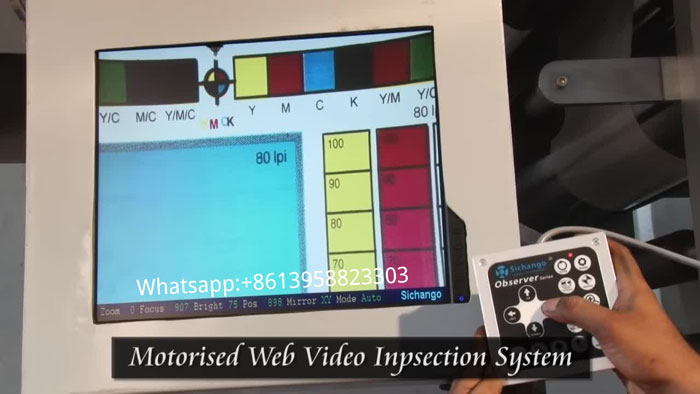

Web Viewer Inspection System Observer Series 4000R

Description

This is a web viewer inspsection system observer series 4000R for the camera video inspection of any type of printing machine such as flexographic, rotogravure, offset, label, rotary, digital and any machine that requires real-time printing quality checking production control available for narrow, medium and wide web applications.

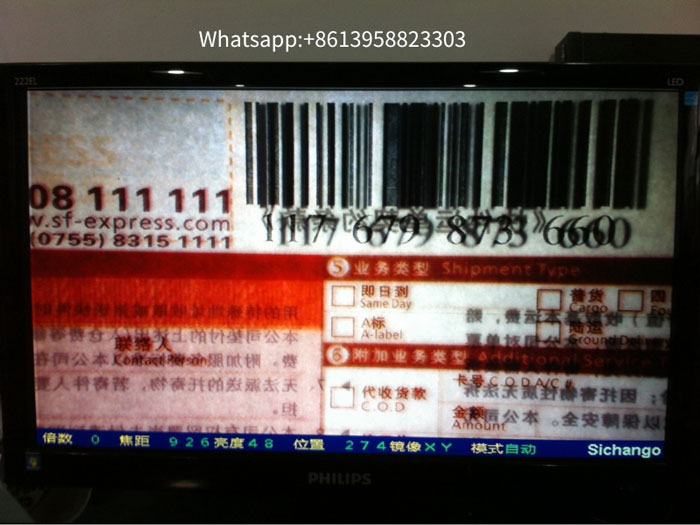

What Is Web Video Inspection System

Web video inspection system-When the printing press is running at high speed, the human eye cannot observe the quality of the printed image. A monitoring system must be used to observe the still image. The web inspection system uses new technologies and methods to turn high-speed moving images into “still” images that are easily accepted by the human eye and can be partially enlarged to detect small printing defects in time, and take improve the quality of printed products, images and real-time images on separate observe.

Observer 4000R

Body keyboard, wire controlled keyboard

Observer3000/4000 series cameras provide a body keyboard

And a wired keyboard. The body keyboard is fixed on the camera, and the wire controlled keyboard

Independent of the camera, installed through cable connection on any part of the printing machine

place The keyboard film is sturdy, corrosion-resistant, and has a long lifespan.

Dual display

The Observer3000/4000 series can be connected to two monitors, both

Suitable for users to install one at the head and one at the tail of the printing machine, and also suitable for remote installation

Installed in any position (requires separate cables).

Long lifespan LED light source

The strobe light uses LED bulbs, combined with our unique longevity technology,

Bringing a uniform and ultra long lifespan light source to the product will greatly enhance

Reduce product failure rates and overall customer costs.

Color value analysis

The Observer series of products innovatively integrates color value analysis functionality

(Colorimeter), which can measure the RGB/CMYK vector values of the measurement points

Measure and display on the screen for convenient user detection due to ink concentration

The color change caused by changes.

Positional memory

The system supports location memory, and users can view the location points they need to view,

Including magnification, focal length, and camera coordinates on the printed material

Record it. Users only need to perform a simple operation on the menu, the system

You can immediately retrieve the storage point and present it on the screen.

Narrow-width Web Video Inspection System

System features

♦ Line motor-move traverse

♦ RGB/CMYK VALUE DETECT

♦ Image Rotate

♦ Image Patrol Shooting

♦ Image Split and Freeze

♦ Image Sharpen with Gamma

♦ Image Roll and Slow Shot

♦ Printing Speed & length measure

♦ Optical multiple & zoom Saving

System Configuration:

Design under ergonomics

Observer series provide camera keyboard and remote keyboard for various rotary presses. Remote keyboard can be installed on camera unit, controller cabinet, or control panel of rotary press. Dual display is also provided. All these can make operation easier than before.

MOTOR DRIVE

It is suit for all kind of printing press with wide press material, or high position, and need camera to move frequently. Observer 4000M had been installed and applied on flexo and gravure press worldwide with hundreds sets.

CMOS high-speed industrial camera

Observer series is using high-speed CMOS industrial camera as the core unit with Sichango own intellectual property. It‘s small and stable with VLSI chip and provide clear, sharp and high-definition image.

Image patrol shooting

Observer 4000M (Motor drive) provides patrol shooting function which can shoot image while camera loops moving on traverse automatically to detect print quality easily. Traverse length up to 3 meters or more.

Clear continuous 30X optical zoom

Observer series are all with 30X optical zoom. It providing fine adjustment from 1X to 100X with advanced digital image algorithms and give clearer image and detail than before.

Wide-width Web Video Inspection System

Simple and easy function for end user

It refine various functions on market and requirements from end users, providing most simple and practical functions in Observer series with new features as CMYK value detect, strobo life protect, auto scan and give end user more ROI in one time purchase.

CMYK value detect

Observer series innovative integrating CMYK value detecting as standard function which can measure RGB and CMYK value and display on screen in real-time value and help user to find color change caused by ink consistency.

Function in Detail Highest response in industry

Observer series provide sensitive features up to 10 pics shoot speed per sec and maximum 400m/min defect running speed beyond other systems on market.

Image freeze and rotate

Providing image freeze and free rotate by X, Y and XY axis. Camera unit can rotate with customer requirements to fulfill web inspection in different angle.

Image split

Image can be split by left freezing one with right updating one in real time to help user to contrast printing result.

Visual Inspection Machine for the Printing and Paper Industry

For all type rotary press

Observer series can fit for various of rotary press such as drum press,combination rotary press and gravure rotary press, etc.

Specification:

|

OBSERVER |

4000M Motorized |

|

COSMOS SENSOR |

2M pixels |

|

OUT PUT RESOLOUTION |

1280x1024 pixels |

|

IMAGE VIEW |

90mmX67,5mm |

|

MAX OPTICAL ZOOM |

30X |

|

MAX. SHOOT SPEED |

10pics/sec |

|

MAX RUNING SPEED |

400m/sec |

|

MOTORIZED |

+ |

|

CAMERA MOVE SPEED |

52mm/sec |

|

VOLTAGE |

110V-240V, 50-60hz |

|

HUMIDTY |

20%-80% |

|

SIZE (LxWxH) |

110x238x290mm |

|

WEGHT CAMERA CONTROLLER |

9kg 3kg 6kg |

|

Printing Registration inspection |

+ |

|

Printing Quality inspection |

+ |

Dual cameras working for OVERSEER 100 MODEL

video web camera Print Image Inspection System for printing machine OVERSEER 200 series

The Overseer 200 series is the latest high-end, all-in-one camera printing quality checking web inspection system

Function:high pixel printing image observation system, the system adopts brand new hardware flat

Platform, supporting a newly customized graphical interface, can be work with touch screen and enhanced lighting Source, can bring smooth operation, powerful functions, and clarity to high-end web inspection system checking rquest customers

Clear and delicate image quality.

Conventional field of view, oversized field of view

Different customers have different requirements for vision, but they can see more paintings at once

Face is an unchanging pursuit. The Overseer 200 series, as well as the newly developed 200x120mm ultra large field of view.

Dual camera collaboration

A product that combines double-sided collaborative printing with front and back overprinting and die-cutting, and a minimalist design

Packaging is increasingly appearing in the market, which is crucial for observing printing images

Tong has put forward new requirements. Simultaneously specifying multiple locations for viewing (fixed-point cruising)

The requirement of quickly scanning the entire layout (full frame scan) is also testing the product. because

This Overseer series supports dual camera collaboration, and both cameras can

To complete fixed-point cruising and full frame scanning on one side, front and back of the printing material

Create a touchscreen graphical work interface and task-based menu for customer operations

Bringing great convenience.

20X optical lens

To achieve perfect image quality, any one of the camera, light source, or lens

We cannot have any shortcomings. We insist on using expensive optical lenses just to

Can bring customers clear and sharp effects that are different from digital amplification, and more

Good display of ink dots and colors, assisting customers in printing exquisite products.

Professional designed LED light sources and cameras

As customer printed materials become increasingly complex, ordinary lighting methods are no longer sufficient

Meet the needs. Therefore, we have hired a professional company to redesign the Overseer series

The light source and camera of the column, in terms of color restoration, clear image, and different materials

The best balance has been achieved in terms of requirements.

Customers can adjust the light source in the camera according to different materials, in order to

The machine and lens provide the most suitable lighting to capture the best results.

Fixed Point Cruise (PPS)

Users can easily manage tasks in the Overseer system

Fixed point cruise, which can be used to focus on observing trademarks, numbers

Decimal points, overprinting crosshairs, and other areas that are prone to printing errors. user

Just specify the position where the camera needs to stay on the rail, while also

You can request the system to take photos at each point to demonstrate the printing effect

, including the size of the image, duration of stay, etc.

Full format scan (AutoScan)

In order to improve printing efficiency, high-speed and wide format printing is becoming a trend in the printing industry

The trend is that the Overseer series can quickly adapt to the width of the printing format

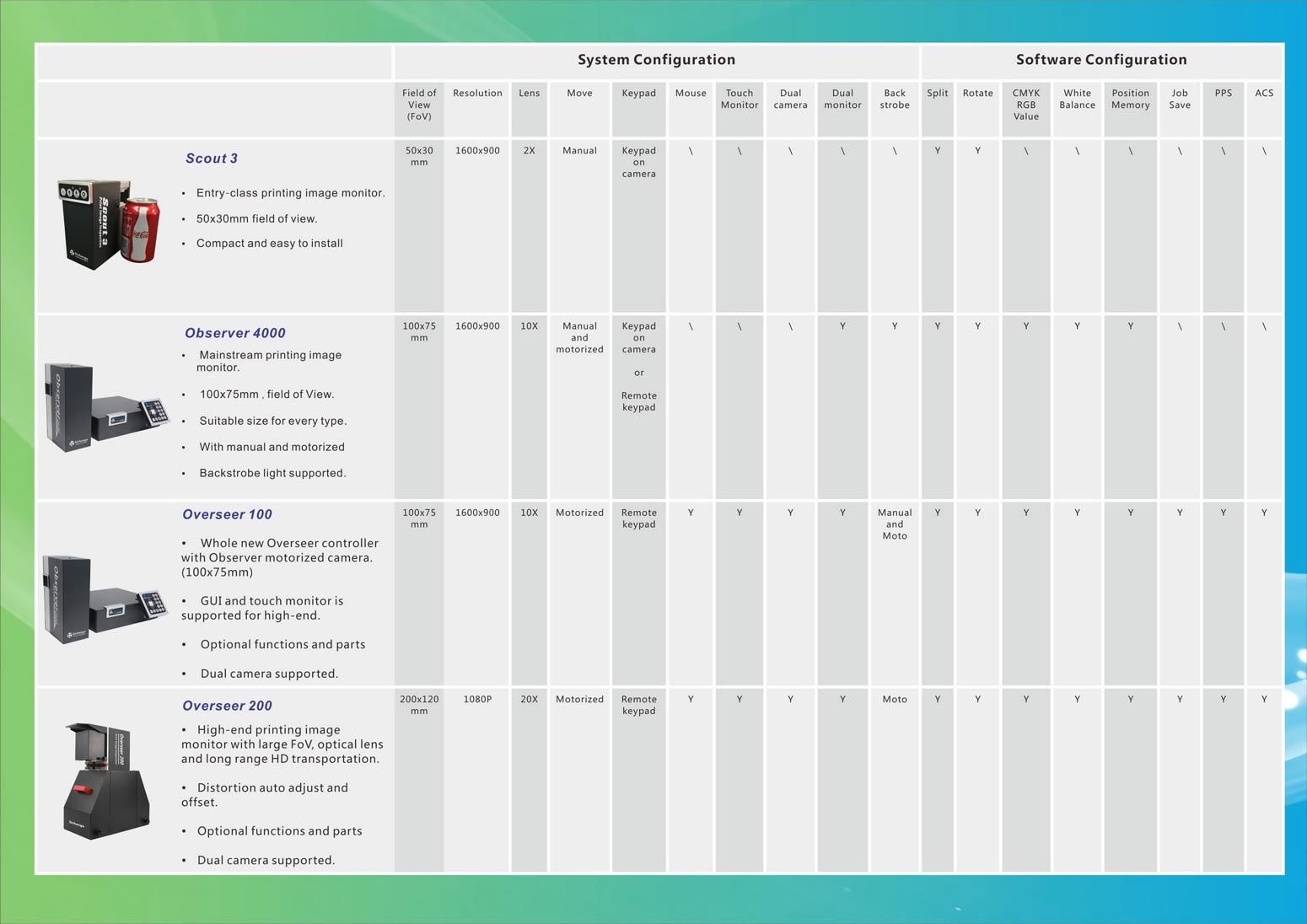

Here is our some models for your choose:

Can be installed in any place or your machine to meet different printing job requests.

.jpg)