- Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

-

Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

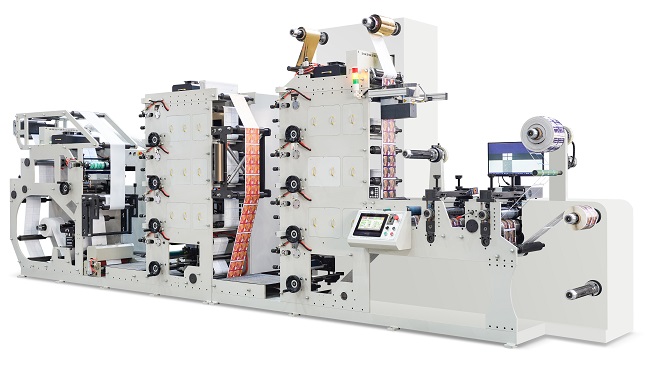

Twin Towers Type Sticker Labels Flexographic Printing Machine

Features MORE EARSIER OPERATION THAN TRADITIONAL STACK TYPE LABEL PRINTING MACHINE

1. The flexo printing machine adopts the anilox rollers to spread ink.

2. Unwinding and rewinding of the flexo printing machine is controlled by magnetism power brake, clutch.

3. Printing unit of the flexo printing machine adopt 360º to regulate for registration.

4. Each printing unit of the flexo printing machine has one IR drier.

5. The rubber roller of the flexo printing machine can break away automatically while parking, and running at a low speed, in order to avoid water being dried.

6. The main motor of the flexo printing machine is adopted the import stepless regulation of frequency conversion.

7. Unwinding, printing, varnishing, IR drying, laminating and rewinding of the flexo printing machine can be finished in one process, this kind of printing machine is best for each printing companies to print on adhesive-paper labels and other commercial label.

Optional part

Cold Stamping Unit

Cold Laminating Unit

Corona System

Independent feeder

PLC Control Board

|

Technical parameter |

|

Standard configuration |

|||

|

Printing speed |

50-60m/min |

Main motor4.0KW |

1-8pcs anilox roller |

||

|

Printing color |

1-10 colors |

Magnetic powder brake 50N (china) |

1-8pcs rubber roller |

||

|

Print max width |

320mm |

Magnetic powder brake 50N (china) |

1-8pcs doctor blade |

||

|

Unwind roll width |

330mm |

Rewind automatic tension control(zhongxing) |

1-8pcs ink fountain |

||

|

Unwind roll diameter |

600mm |

Frequency converter 4.0kw(Schneider ) |

|

||

|

Rewind roll max diameter |

600mm |

Fan (China) |

|

Accessory |

|

|

Printing length |

175-410mm |

button (Schneider/Delixi) |

|||

|

Registering accuracy |

±0.15mm |

Waste collection device |

|

||

|

Voltage |

380V±10% |

Laminating device |

|

||

|

Total power |

Around 33kw |

Die cutting device |

Tool box |

||

|

Air press |

0.6MP |

Correction device Zhongxing |

12pcs Bottom mat |

||

|

Oil system |

Manual |

Corona device |

|

||

|

Weight |

3500kg |

|

|

||

|

Dimension |

2700 X 1400 X 2650mm |

|

|

||