- Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

- Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

Square Bottom Paper Bag Making Machine

Product Description

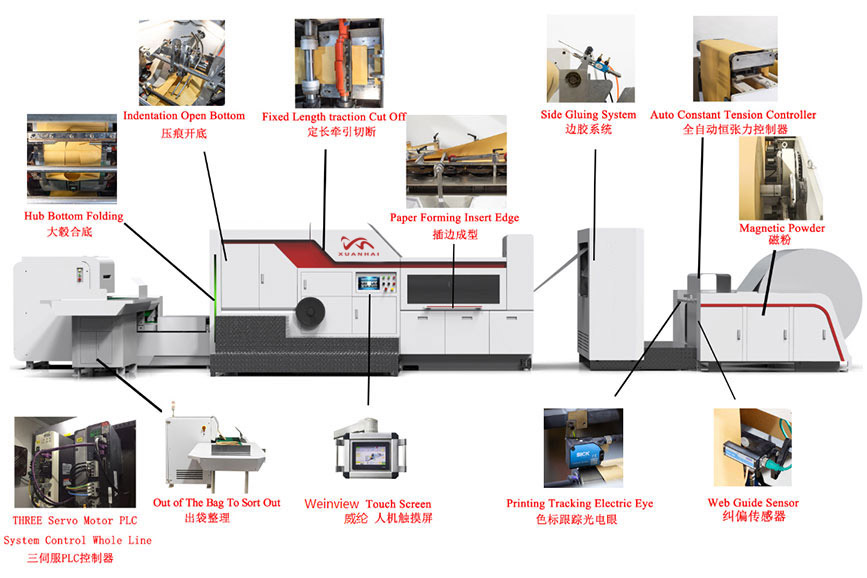

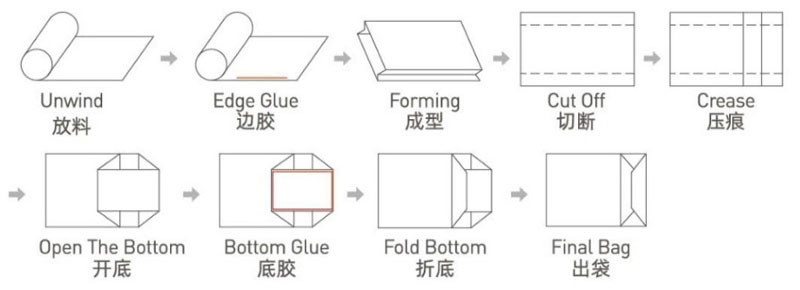

Roll feeding square bottom paper bag machine use the original paper rolls or printed paper rolls as the raw materials to produce the variable size square bottom paper bags. The machine is totally automatic and controlled by Mitsubishi servo motor. The producing process are paper roll loading, side gluing, forming, cutting, bottom opening, bottom gluing and bottom close, the delivery the paper bags. There are two options of the paper bags collect to match customers’ different requirement. Depend on different requirement, the machine can add printing inline to produce the paper bags with logo or picture, also can add the d cut device to produce the paper bags with d cut handle.

Machine Parameters

| Model | FD220 | FD280 | FD330 | FD450 | FD540 |

| Bag Tube Length | 190-370mm | 270-530mm | 270-530mm | 270-530mm | 400-770mm |

| Bag Length | 150-320mm | 225-470mm | 225-470mm | 210-460mm | 320-680mm |

| Bag Width | 80-220mm | 120-280mm | 150-330mm | 220-450mm | 250-540mm |

| Side Insert Depth | 25-60mm | 30-90mm | 30-90mm | 40-110mm | 60-130mm |

| Bottom Width | 50-120mm | 60-180mm | 60-180mm | 80-220mm | 120-260mm |

| Side Edge Width | 20-30mm | 20-30mm | 25-30mm | 25-30mm | 30mm |

| Bottom Edge Width | 10-25mm | 15-30mm | 15-30mm | 20-30mm | 20-30mm |

| Paper Thickness | 50-130g/㎡ | 60-160g/㎡ | 60-160g/㎡ | 80-160g/㎡ | 90-160g/㎡ |

| Paper Inner Core Diameter |

ᴓ76mm(3”) | ||||

| Paper Roll Diameter | ᴓ1200mm | ||||

| Paper Roll Width | 280-710mm | 380-950mm | 450-1050mm | 630-1370mm | 770-1630mm |

| Bag Making Speed | 30-200pcs/min | 30-180pcs/min | 30-160pcs/min | 30-150pcs/min | 30-120pcs/min |

| Air Source | ≥0.12m³/m 0.6Mpa | ||||

| Power Supply | 10kw | 12kw | 12kw | 15kw | 18kw |

| Machine Weight | 5500kgs | 7000kgs | 8000kgs | 10000kgs | 11500kgs |

| Machine Dimension | 9000X3200X1800mm | 10500X3600X1900mm | 10500X3700X1900mm | 10500X3800X1900mm | 11500X3900X1900mm |

Machine Details

Bag Producing Process

Samples