-

Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

- Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

Automatic Pre-fold & Lock Bottom Folder Gluer machine

Product Description

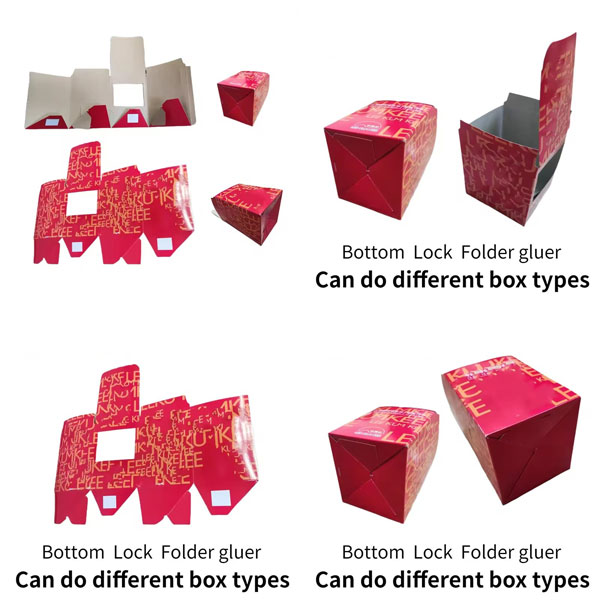

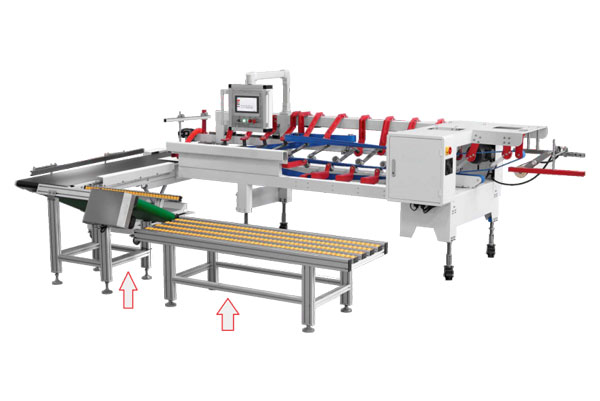

This machine is specially used for paperboard shaping and adhesive processing after cutting horizontally. Its universality is strong and suitable scope is wide, which can fold and paste various straight seaming box and bottom edging box.

It is widely used in food, medicine, cosmetics, stationery and other ordinary cartons, process and glue for all kinds of bottom-locked cartons.Pre-fold section is applied to auto packaging, fold 1 and fold 3 of all cartons can reach 180° and 135° , perfectly combing the requirements of auto packaging together.

Machine Parameters

|

Model |

SHH-800AKJ |

|

Paper Material |

Cardboard 200-800g E-flute F-flute |

|

Max. Liner speed |

Max. 280 meter/minute |

|

Feeding way |

Automatically and continuously feeding |

|

Way of folding |

Fold 1 and fold 3 are 180°and 135°, Fold 2 and fold 4 are 180°, Bottom folded and glued |

|

Glue Material |

Water-base cold glue |

|

Electric power |

7.5KW 380V 50HZ 3P |

|

Weight |

3300KG |

|

Machine dimension |

12700 x1500x 1400mm |

Feature introduction

|

Feeding Adjustable feeding belts to ensure easy adjustment, stable and smoothly feeding. Continuously Variable Speeder to ensure feeding internal and stable transmission. One-touch Pneumatic knife, easy for the adjustment of feeding belts. |

|

Alignment Alignment section, which automatically corrects the box after it is ejected from the paper feed section. |

|

Pre-fold Double-board structure with a set of pre-folding knife. Pre-fold angle is 180°, especially suitable for small but high cartons, more satisfactory while rapid prototyping. |

|

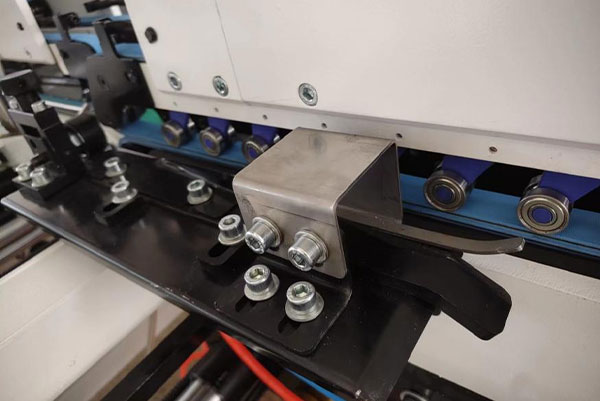

Bottom-lock 3-board tracking structure, upper gluer can make bottom-locked box automatic gluing and forming, can be used for the special-shaped cartons. The entire bottom-lock part is installed in a reversible bracket, substantially reduce the swap adjustment time of bottom-fold box and the other types of box. Bottom-folding speed is 50-200 pcs per min, stable and reliable. |

|

Folding Lengthened folding to avoid the unevenness while the rapid forming of cartons and make it come to perfection. |

|

Full pressing With counting device to count the finished boxes to match with boxes regulating, easy to count and pack. |

|

Transmission Equipped with feeding paper inspection device. Equipped with impacting device to press the paper after accounting and make it easy to pack paper. |

|

The Grinding part More effective treatment of paper surface UV, the carton adhesive more stronger |

|

CCTV monitors The machine adapt CCTV monitors could see machine product |

|

Touchscreen The machine adapt touchscreen adjustment, fast to adjust |

|

Spraying System (water-base cold) For irregular box, Need Extra Spraying System. |

Machine Optional configuration list

|

Optional hot melt system The tank less hot melt system is designed for melting and pumping of thermoplastic hot melt in granulate form. It gently melts on demand and therefore is applicable for both high and low glue consumption applications. Optional volume control monitors changes in adhesive consumption. Thanks to the fast heat-up time of 16 minutes to 160 °C the Concept Stream is quickly operational. In addition, the adhesive system achieves a high melting rate performance of 8 kg/h or 15 kg/h with minimum space. |

|

Optional Plasma system Through surface coating treatment, to strengthen the adherence and make cartons easier to be glued. |

|

Optional Box collection device The machine reduces labor intensity, saves manpower, improves the working efficiency of the folder gluer machine, and can make the performance of the folder gluer machine fully play. |

|

Optional banding Machine The machine reduces labor intensity, saves manpower, improves the working efficiency of the folder gluer machine, and can make the performance of the folder gluer machine fully play. |