- Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

- Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

-

PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

HZ-260D High speed PVC PET Shrink Sleeve Seaming Machine

Product Description

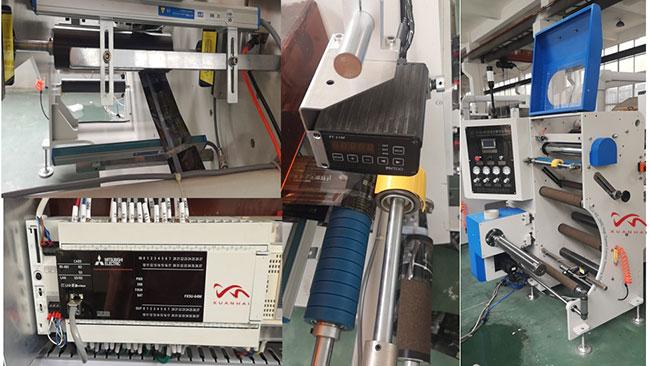

This HZ-260D Mouldless type 400m/min High speed Shrink Sleeve Seaming Machine is with glue pump system (we also have needle gluing system)

PVC PET shrink sleeve seaming machine is designed to join or seam PVC or PET sleeves together, typically in an industrial setting where high-speed and precision are crucial. The working process of such a machine can vary depending on its design and technology, but here's a general overview of the working process:

Unwinding system

1. Unwinding shaft is 3 inch air shaft.

2. Edge position correction system: Photo sensor get the signal and send it to controller. Controller give the signal to execution equipment and keep straight film edge.

3. Unwinding tension controlling system: It use servo automatically and accurately control unwinding tension .

4. Air extrude device

It makes small holes on the film, when the label shrink in the tunnel, the air will extrude via the small holes.

5. Double vertical perforation device

Forming system

Mold less type: It solves the problem of the film scratches during the machine working

Width adjusting: The machine adjusts the width by scale wheels,it can adjust accurately and easily when changing the width of label.

Forming tension control: use two servo motor to control forming tension softly and accurately.

Pump Gluing system is controlled by PLC. It will keep the same step with the machine running speed and make the glue well distributed. Gluing quantity controlling system can control the glue quantity, machine stop glue getting back, no pollution on film, operation easily.

Rewinding system

1. Rewinding shaft adopt 3inch air shaft.

2. Rewinding tension controlling system: Servo motor automatically and accurately to control the tension.

3. Stroboscope

It keeps the same step with the machine, it’s easy to detect the gluing condition when high speed.

4. Oscillation rewinding system: Use servo motor control the shrink sleeves roll move left to right . The parameter of it can be set by touchscreen.

5. Static eliminating eliminator.

6. The machine can keep 100 group data for easier operation.

Machine Parameters

|

Model |

HZ-260D |

|

Materials |

OPS,PVC,PET |

|

Film thickness |

20-80 um |

|

Width of unwinding |

580mm |

|

Max.Unwinding diameter |

Φ500mm |

|

Rewinding width |

25mm-240mm |

|

Max.Rewinding diameter |

Φ900mm |

|

Max speed of Machine |

420m/min |

|

Power |

3 Phase 220V 60HZ |

|

Supply Power |

7KW |