- Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

-

Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

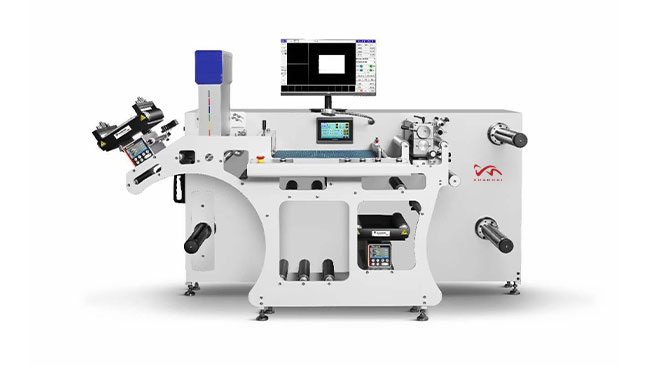

Automatic Sticker Paper Label Inspection Machine With Slitting System

Features

Automatic Stop when the camera finds Defective products

This printing quality inspection machine mainly check final printed label quality such as Paste words, missing printing, dirty spots, overprint deviation, color difference, Fundamental defect ,Gold stamp defect, cold stamp defect ,Overflow ,scratch ,Bubble and so on

Popular used in food,daily chemical electrical label printing process quality defect

The inspection system mainly includes high-speed cameras, industrial-grade lenses, LED light sources, signal interaction, image processing software and mechanical supports. Among them, line scan cameras, lenses, image capture cards and other important components are all of high quality, stable and reliable; customized equipment such as light sources, signal interaction and mechanical brackets are all produced or customized brands, under the premise of ensuring quality, flexibly grasp and fully Consider the special needs of customers.

Main technical parameter

|

Model No. |

JPJ-350 |

|

Detection area |

350*350 |

|

Coil diameter |

600mm |

|

Maximum detection speed |

80m/m |

|

Accuracy of point defect detection |

0.1mm |

|

Chromatic aberration detection |

△E≤1 |

|

Test Item |

Chromatic aberration. White spot. Black spot. Missed print. It's an Anagram. It's a scratch. Air Bubble. Die Cutting sleeve |

|

Detection of MISREGISTER/Striping accuracy |

±0.1mm/±0.1mm |

|

SCOPE of application |

One-dimensional Code. Two-dimensional code. Oã ° é. English. Chinese. Symbols. Numbers, wait |

|

Camera |

DALAS |

|

Paper weight |

40-350g |

|

Machine size |

2250*1300*1700 |

|

Mechanical inspection speed/ Opitional :Maximum sltting speed |

Inspection 80m/m slitting 300m/min |

|

Capture the tag image |

Optional |

|

2d Code Data |

Optional |

Slitting funcation specification

|

supply voltage |

Single phase 220V 50 / 60Hz |

|

Power size |

2.2KW |

|

Maximum feeding width |

350mm |

|

Maximum slitting size |

350mm |

|

Machine dimensions |

2480x1200x1800mm |

|

Slitting speed |

50-300r/min |