- Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

- Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

Waste Box Cutting Corrugated Kraft Paper Cardboard Shredder

Product Description

Is your company still troubled by too much waste paper?

Are you still worried about how to pack environmentally friendly for the ban on plastics?

Are you still looking for suppliers for expensive packaging fees?

Don't panic,We help you solve this problem!

Cardboard box shredder is a new developed environmental product. It produces packing filler materials by using old cardboard boxes, save money on packing material and help the environment by recycling.

Expansion cutting machine use

The waste paper is used for waste utilization, and then cut into honeycomb paper for express delivery, logistics, packaging and delivery of fragile and fragile items.

The advantages of the puffing machine

①Green and environmental protection: The paper packaging filler can be recycled and has no pollution source; it can be used as a substitute for "plastic packaging", which perfectly complies with the "plastic ban".

②Reduce costs: The recycling price of discarded corrugated cardboard is about 400 yuan/ton. After being processed into honeycomb paper, the value will be about 10 times the original value, which can greatly reduce the cost of enterprises.

③Waste utilization: It can deal with irregular waste cardboard, carton, pearl cotton, A4 paper, etc. for recycling, which greatly solves the more difficult problems of enterprise managers.

④Wide range of uses: The reticulated corrugated cardboard processed by the bulking machine can be widely used as packaging filler for the packaging and logistics of precision instruments, electrical appliances, ceramics, glass, handicrafts, cosmetics, furniture and other items.

Model parameters of the puffing machine

|

Model |

Large 425 |

Medium 325 |

Small Desk Type 255 |

|

Cutting width |

425mm |

325mm |

255mm |

|

Cutting thickness |

13mm |

7mm |

6mm |

|

Suitable |

Corrugated paper/A4 paper pearl cotton |

Corrugated paper/A4 paper pearl cotton |

Corrugated paper/A4 paper |

|

Shredding speed |

13m/min |

9m/min |

3m/min |

|

noise |

60db |

60db |

60db |

|

voltage |

380V,50hz |

220/110V, 50hz |

220/110V,50hz |

|

power |

2.2 kw |

1.5kw |

0.1kw |

|

Machine size |

623*385*886mm |

487*378*826mm |

387*316*380mm |

|

weight |

127kg |

78kg |

31kg |

The operation method of the paper skin puffing machine

①After the machine is powered on, the switch is turned to the left (1), the machine is running normally, and the paper feeding can be started;

②If there is a paper jam during use, turn the switch to the right (2) to rotate the machine in the reverse direction to eject the jammed paper, then rotate it to the left to re-feed the paper and expand it;

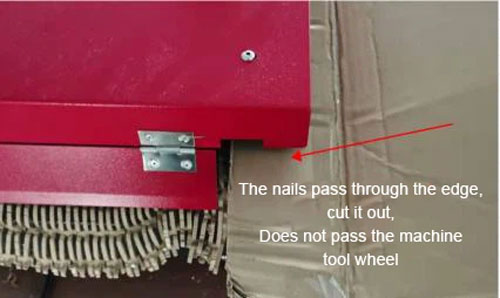

③Because the cutter wheel is thin, it is best not to put the iron nails on the carton into the machine for expansion cutting, so as not to reduce the life of the machine or cause malfunctions (the iron nails can be cut off through the left side of the machine, as shown in Figure 1).

Routine maintenance of paper skin puffing machine

①After the machine is powered on, do not open the top cover to avoid accidental injury when the machine is running;

②Clean up scraps of paper every 1-2 months (according to the length of use) (Figure 1 and Figure 2) and add lubricating oil (Figure 3).

|

|

|

| Figure 1 at the knife wheel | Figure 2 Paper outlet | Figure 3 Chain and gear |

Display of waste paper products