- Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

- Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

Fruit Vegetables Packaging Machine

Customized product

(We can customize the suitable one for you according to your requiredment.Just Tell us : Weight or Bag Size required.)

Product Paramenters

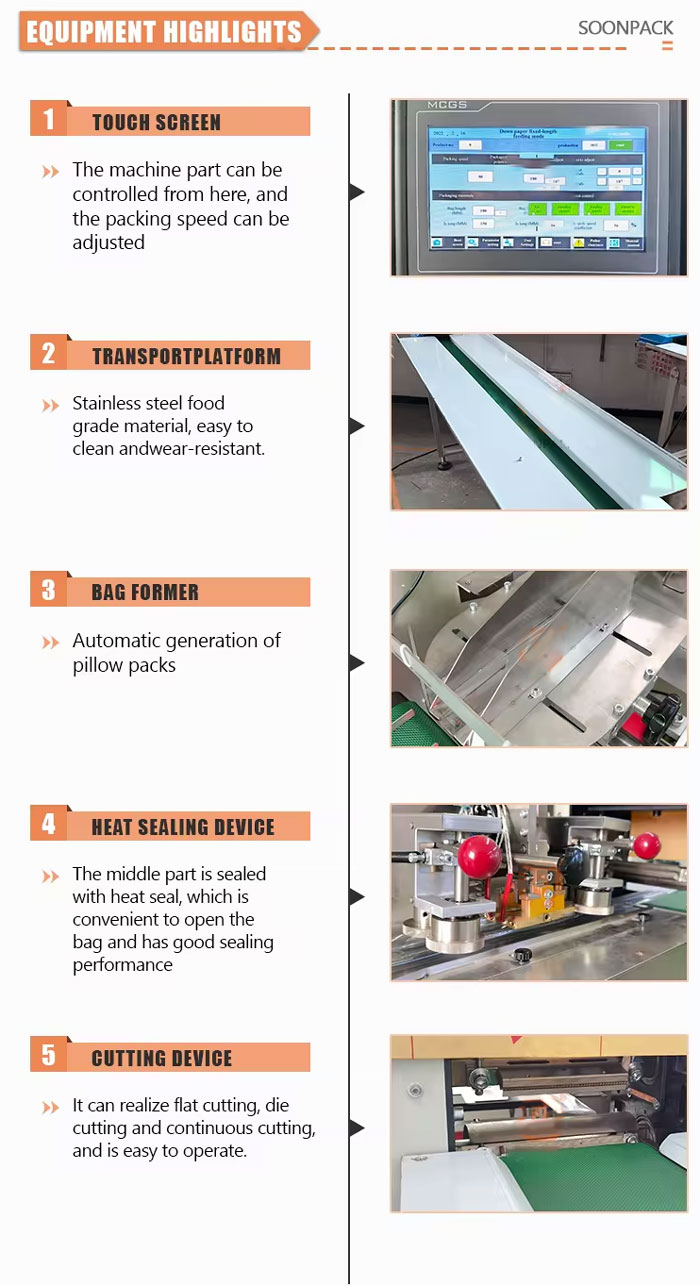

Machine characteristics and parameters

1. Double frequency conversion control, the bag length canbe set and cut, no need to adjust the air, one step in place, saving time and film.

2. Man-machine interface, parameter setting is convenient and quick.

3. Fault self-recognize function, fault display at a glance.

4. High-sensitivity photoelectric eye color tracking, digital input sealing position, make sealing position more accurate.

5. Temperature independent PID control, better suitable for various packaging materials.

6. Positioning stop function, no sticky kuife, no waste film.

7. The transmission system is simple, the work is more reliable, and maintenance is more convenient.

8. All control is implemented by software, which is convenient for function adjustment and technical upgrade, and never lags behind.

| Model | SP-250X | SP-350X | SP-450X | SP-600X | SP-700X | SP-800X |

| Film Width | Max.250mm | Max.350mm | Max.450mm | Max.600mm | Max.700mm | Max.800mm |

| Bag Length | 45~190mm | 65~280mm | 120~450mm | 130~450mm | 120~600mm | 120~600mm |

| or 90~330 mm | or 90~330mm | |||||

| Bag Width | 30~110mm | 50~160mm | 60~210mm | 60~280mm | 50~330mm | 50~380mm |

| Product Height | Max.40/70mm | Max.45/80mm | Max.110mm | Max.150mm | Max.150mm | |

| Roll Diameter | Max.320mm | |||||

| Packaging Speed | 40~200 bags/min | 30~150 bags/min | 20~120 bags/min | |||

| Machine Power | 220V,50/60Hz,2.4KW | |||||

| Machine Size | 3770*670 | 3770*720 | 3770*720 | 4020*770 | 3990*900 | 3990*1000 |

| (L*W*H)mm | *1450 | *1450 | *1450 | *1450 | *1468 | *1468 |

| Machine Weight | 800kg | 900kg | 1050kg | |||

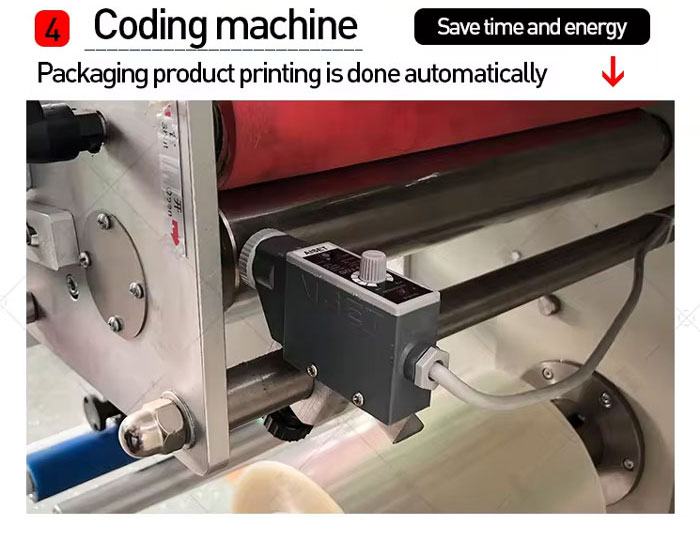

| Optional Device | Date Coder, Air-filling Device, Punching Device | |||||

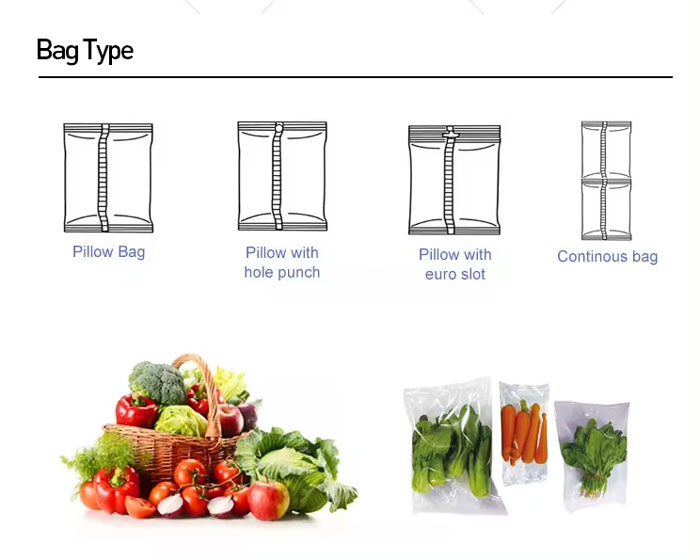

Packing Effect

The effect after packaging is back-seal bag. According to demand, other devices can be customized or upgraded to meet other models. For example, pillow bag with hole, bag with label, gusset bag, etc.

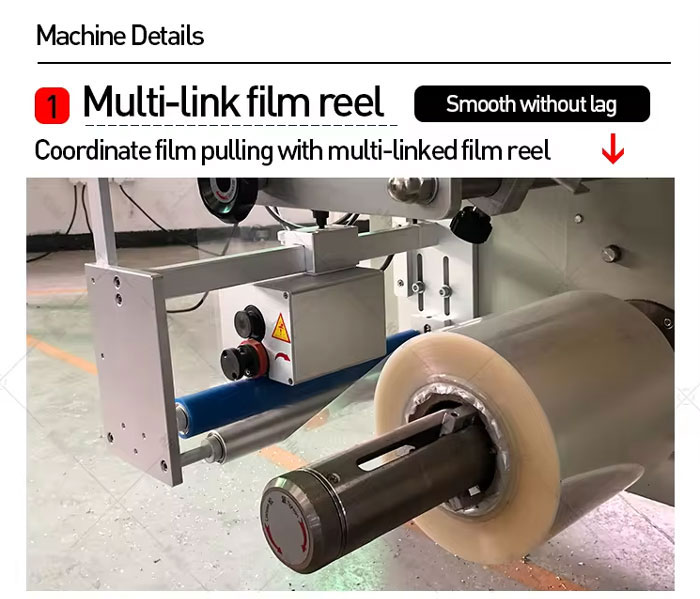

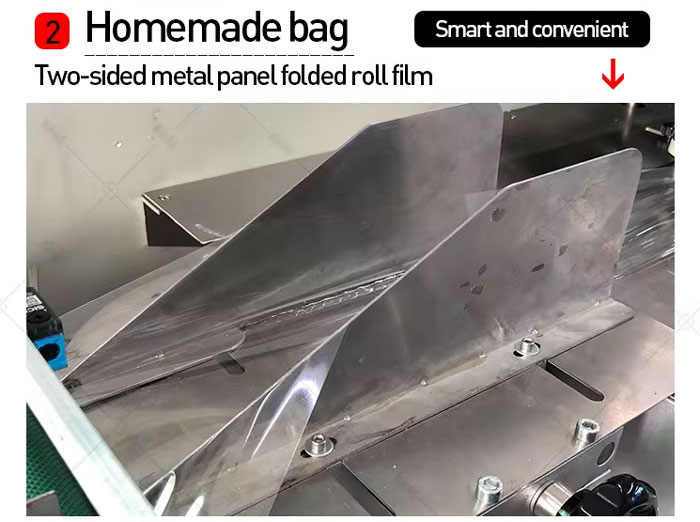

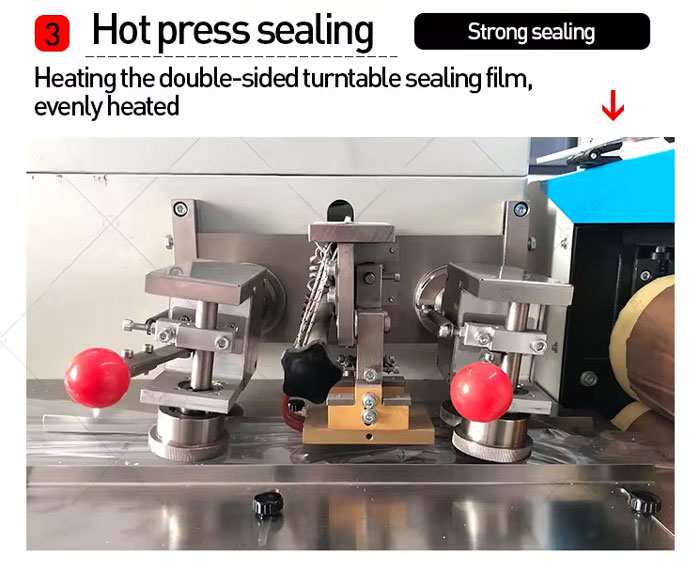

Machine Details