-

Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

- Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

Paper Stick Making Machine

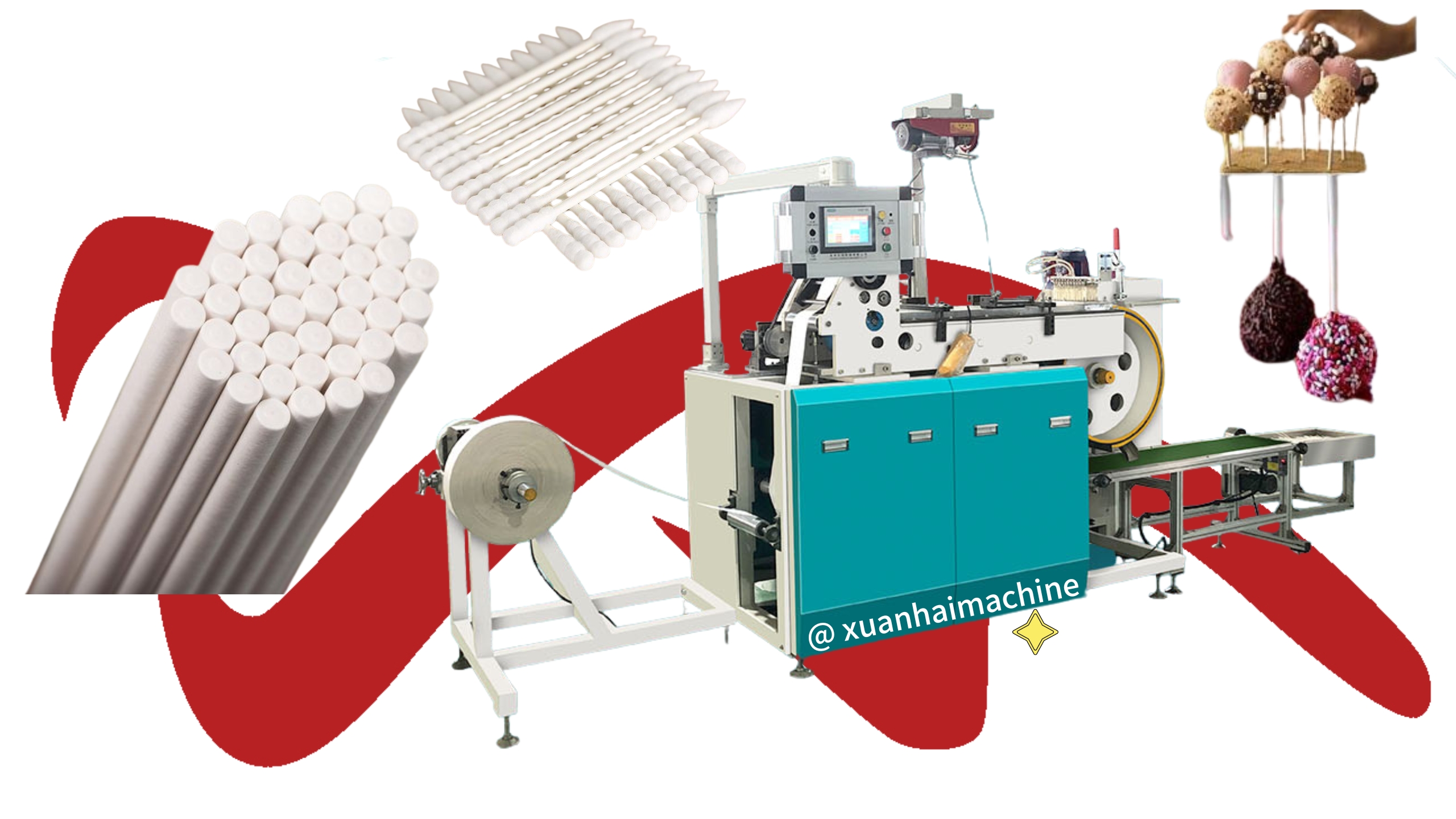

Fully Automatic Paper Stick Making Machine

Abstract

Here we introduce details of an innovative paper stick making machine. With a focus on sustainability and eco-friendly materials, the machine efficiently produces paper sticks for various applications, including cotton swabs, lollipops, and stirring sticks. The automated system ensures precision, speed, and cost-effectiveness in the manufacturing process.

Introduction

1.1 Background:

The increasing global awareness of environmental sustainability has led to a demand for alternatives to traditional plastic products. Paper sticks, made from biodegradable materials, have emerged as a promising substitute in various industries.

1.2 Objectives:

The primary objective of this paper is to introduce and describe the design and operation of a state-of-the-art paper stick making machine. The machine is aimed at revolutionizing the production process by combining efficiency with environmental responsibility.

Design

2.1 Material Selection:

The machine is designed to use recycled paper or sustainably sourced paper as the raw material. The chosen material ensures the final product's biodegradability and eco-friendliness.

2.2 Machine Components:

The paper stick making machine comprises several key components:

a. Raw material feeder

b. Paper cutting mechanism

c. Gluing station

d. Stick forming unit

e. Drying system ( need another seperete machine)

2.3 Automation and Control:

The machine features a PLC (Programmable Logic Controller) system to automate the entire production process. This allows for precise control over each stage of stick formation, ensuring consistency and quality in the final product.

Operation

3.1 Raw Material Feeding:

The paper rolls are fed into the machine through the raw material feeder. The rolls are carefully selected for quality and consistency.

3.2 Paper Cutting Mechanism:

A high-precision cutting mechanism cuts the paper into appropriately sized strips, ensuring uniformity in each paper stick.

3.3 Gluing Station:

The cut paper strips pass through a gluing station where a biodegradable adhesive is applied to facilitate stick formation.

3.4 Stick Forming Unit:

The glued paper strips are then formed into cylindrical shapes, creating the paper sticks. This process is carried out with precision to ensure the desired dimensions and structural integrity.

4. Conclusion:

The described paper stick making machine offers a sustainable and efficient solution for the production of eco-friendly alternatives to traditional plastic sticks. Its automated design, precision control, and use of biodegradable materials contribute to a more environmentally conscious manufacturing process. The adoption of such technologies is crucial in promoting a greener future for various industries.

Main technical datas

|

Paper rod diameter |

2.5-4mm & 4-6mm |

|

Paper stick length |

50-220mm(length can be customized) |

|

Productivity |

400-1000pcs/min |

|

Paper thickness |

60-100g/m² |

|

Applicable glue |

Polyvinyl alcohol glue, starch glue |

|

Paper requirements |

single glossy paper |

|

Power Supply |

380V 50HZ |

|

Total Power |

8KW |

|

Feed table size |

1180*1210*950mm |

|

Dimensions |

2230*1100*2200mm |

|

Receiving table size |

2100*550*640mm |

|

weight |

2000KGS |

If the low price friendly eco paper stick forming machine meet your requirement, welcome to buy discount and good machine made in China from our factory. We are one of the leading China machine manufacturers and suppliers.