- Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

- Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

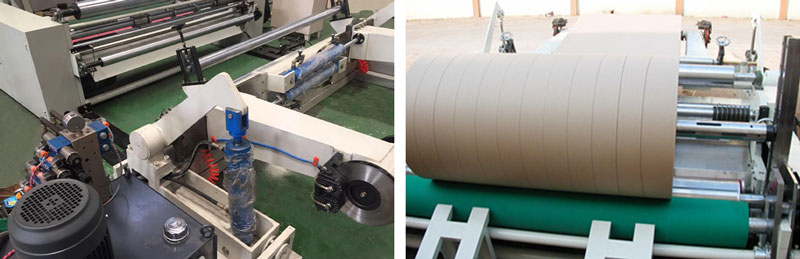

Paper Roll Slitting and Rewinding Machine

Product Description

Paper Roll Slitting and rewinding Machine

According to different requirement of material slitting, this paper roll slitting machine is suitable for paper, aluminum foil, BOPP,CPP, CPE,PVC and other rolled material to slit. The machine is controlled centrally by PLC (three vector motor) and operated centrally by touch screen man-machine interface. Air brake controls unwinding and constant tension control is realized by automatic calculation of coil diameter by PLC.

Machine Parameter

|

Model |

HFQ-1300 |

HFQ-1600 |

|

Max Paper roll width |

1300mm |

1600mm |

|

Rewind diameter |

Φ1300(mm) |

Φ1300(mm) |

|

Max Rewinding Diameter |

Φ1300(mm) |

Φ1300(mm) |

|

Slit width |

>40(mm) |

>40(mm) |

|

Slitting Precision |

<0.1(mm) |

<0.1(mm) |

|

Paper gsm |

20-300gsm |

20-300gsm |

|

Power |

36kw |

40kw |

|

Paper on the way |

Hydraulic |

Hydraulic |

|

Brake |

Double Pneumatic |

Double Pneumatic |

|

Unload |

Pneumatic |

Pneumatic |

|

Speed |

300m/min |

300m/min |

|

Operator |

1 |

1 |

|

Weight |

4500kg |

5000KG |

|

Machine dimensions (L×W×H) |

4.5*3.2*1.9m |

4.8m *3.2m *1.9m |

Features

1. Using steel plate to form the machine body, so the machine can rectify the deviation and accurately in high speed.

2. The unwinding and rewinding adopts 3-inch cone-shaped bottom head clamp, no shaft unwinding, the maximum diameter can reach 1300mm.

3. Automatic edge alignment, automatic knife positioning device, automatic edge correction and standard configuration of manual oil pressure tension control.

4. Adjust blades between 30mm-1600mm.

5. PLC digital control, touch screen set mass production, Chinese and English operation interface.

6. Pneumatic tension control for feeding the raw materials save labor in production, so as to improve production efficiency.

Machine Detail

Machine Configuration

A. Operation control mode

Whole machine control mode

B. Unwinding Unit:

1:Unwinding maximum diameter: 1300mm hydraulic lifting

2:Unwinding tension control mode: Pneumatic brake

3:Loading and unloading method: 3 inch full air shaft loading and unloading

4:Web Guide system: automatic edge alignment

C. Rewinding Unit:

1. Maximum rewinding diameter: 1300mm

2. Method of loading and unloading: front and back loading and unloading

3.Rewinding and pressing method: Inflatable chain type

4.Double roll central rewinding

D. Slitting Unit:

1. Blade 10 pieces

E. Main Drive:

1. Structure: traction Traction 1 steel roll +rubber roll .Traction 2 steel roll

2.Transmission mode: motor active traction, synchronous belt asynchronous servo motor 7.5KW

3.synchronous belt

4.Feeding roller: aluminum guide roller

5.PLC control: 7 inch touch screen

6. Voltage:3-phase 4-wire 380V

F. Additional Unit:

1. Scrap material blowing device

2. Work protection device

Samples