- Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

- Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

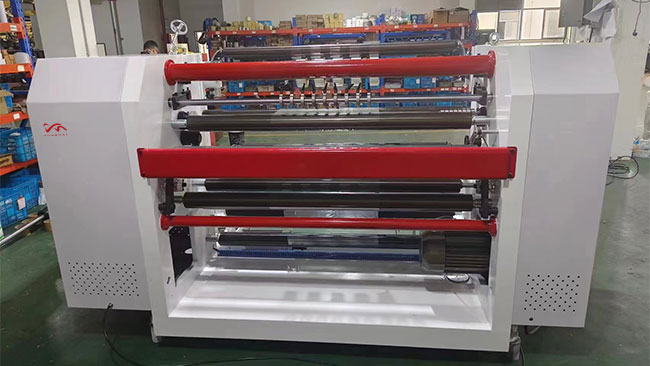

Automatic Vertical roll Slitting Machine

Product Description

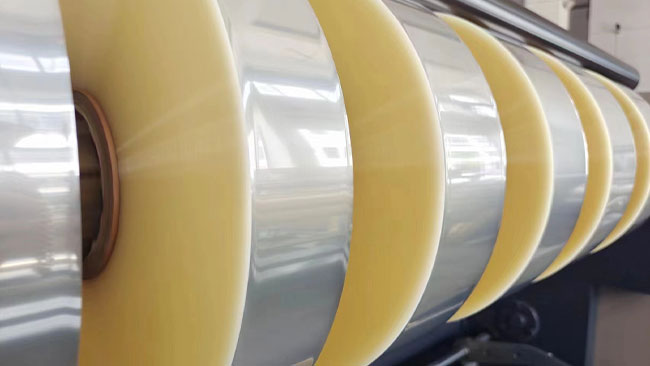

This machine is suitable for slitting various roll materials such as BOPP, PET, CPP, CPE, PVC, etc. During the production process, the materials can be trimmed and slit according to different needs.

Advantage

This machine uses a three-phase asynchronous motor to maintain smooth operation during acceleration; (using variable frequency speed regulation)

Automatic meter counting, alarm and other functions;

The winding adopts A and B air-expanding shaft structures, making loading and unloading easy;

The unwinding adopts photoelectric automatic deviation correction system, so that irregular materials can be cut normally.

Automatic waste edge discharge device for flat knife longitudinal cutting

Manual loading, air expansion shaft (key bar type) 3 inches Φ76mm.

Machine Parameter

|

Model |

LS9-1300 |

| Cut thickness | 20g-300g/m2 (Depending on the different raw materials) |

| Maximum diameter of raw material release | φ600mm |

| Maximum diameter of raw material winding | Φ500mm |

|

Maximum width of raw material |

1300mm |

|

Wiling tile air expansion shaft |

φ76mm |

|

Also roll up the number of axes |

2 pieces (single-axis winding) |

|

Correction accuracy |

±0.5mm |

|

Desection accuracy |

±0.5mm |

|

velocity |

10-200m/min |

|

aggregate capacity |

5kw |

|

Body color |

Gray, shell white (optional colors) |

|

Automatic photoelectric deviation correction is adopted |

(According to the different raw materials and the specific customer requirements) |

Machine Configuration

| Unwinding part | |

| The frame adopts casting structure |

120# high-quality casting structure 45* steel support |

| Photoelectric correction system | Correction accuracy: ±0.5mm 1 set |

| Magnetic powder tension control | 10-50N.M |

| Correction host | 90 type synchronous motor drive 1 set |

| Magnetic powder tension | 5kg controller 1 set |

| Photoelectric eye tracking correction | 1 set |

| Feeding shaft | 1 air shaft feeding |

| Manual operation of substrate | Left and right, parallel adjustment |

| Transmission guide roller | Aluminum guide roller after dynamic balancing treatment |