- Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

- Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

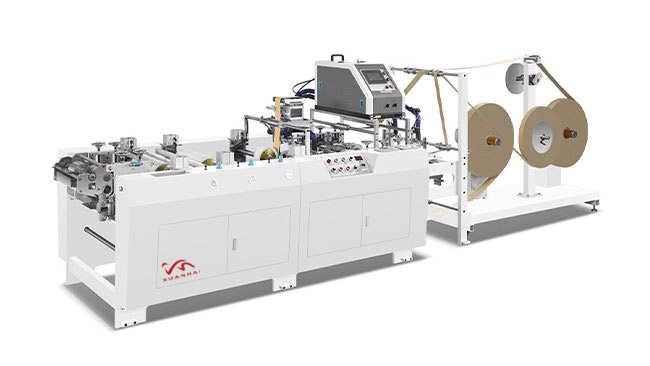

Flat Handle Making Machine

Product Description

The flat handle machine use the four paper rolls to produce the flat rope and then through the belt conveyor to cut off and paste the paper bags ans flat handle together with the hot melt adhesive. This is machine is supported for the production of shopping paper bags with the flat handle, the cost is high performance, so it is the ideal machine for customer’s limit budget and high speed of production.

Product Parameter

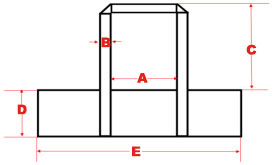

| Handle Spacing(A) | 108mm |  |

| Paper Rope Width(B) | 12mm/15mm | |

| Paper Rope Height(C) | 100mm | |

| Paper Width(D) | 40mm | |

| Paper Length(E) | 152/190mm | |

| Paper Rope Length | 352mm | |

| Paper Gram Weight | 100-120gsm | |

| Production Speed | 6000pairs/h | |

| Power Requirements | 380V | |

| Total Power | 10KW | |

| Total weight | Appr.4000kg | |

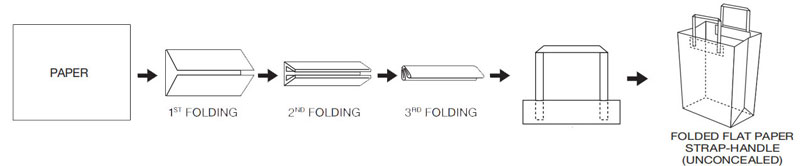

How to produce a paper bag with flat handle?

You need the following machine:

1.slitting machine (optional)

2.printing machine (optional)

3.square bottom paper bag making machine

4.flat handle making machine/flat handle making and pasting machine

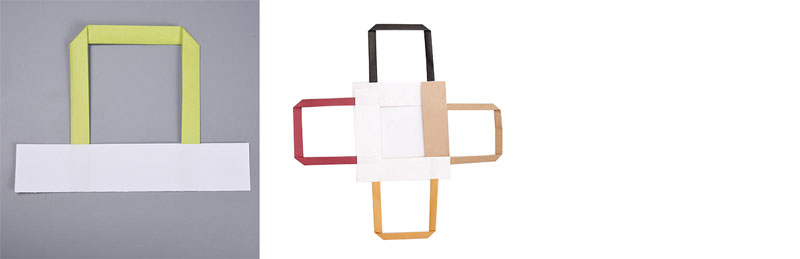

Samples

Feature

1. Simply Operation

2. High speed to adjust

3. Strong bearing capacity

4. High cost performance