- Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

- Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

2 4 6 8 Colors Paper Bag Flexographic Printing Machine

Product Description

The flexo printing machine is widely used in paper production, it is an economical equipment for printing bag paper, cup paper which use the water-based ink. Customer can get different printing size and quality if change the printing cylinders and anilox rollers. We supply the flexographic printing technology, can offer a range with 1 to 6-color and machine widths ranging from 800 to over 1500 mm. It is an ideal printing equipment for food paper packaging, supermarket handbags, vest bags, clothing bags, etc.

Machine Parameter

| Model of Machine | YT-4800 flexo printing machine (4 colors) |

| Max.Width of Printing Material | 800mm |

| Max.Printing Width | 760mm |

| Length Range of Printed | 191-914mm |

| Max.Diameter of Roll Material | ф1000mm |

| Printing Speed | 80m/min |

| Thickness of Plate (Including double-sided tape) | 2.38mm |

| Total Power | 10kw |

| Machine Dimension | 2300×2060×2145mm |

| Machine Weight | 2000kg |

Features

1. Easy to operate, accurate colors, long life using.

2. Heating devices to make sure the ink can dry quickly.

3. Printing quality is good and clear.

4. Skewed tooth, accurate printing size.

5. variable frequency speed control adapts to different printing speeds.

6. 360-degree continuously adjustable longitudinal register device.

7. The printing ink is spread by the anilox cylinder with even ink color.

Machine Point

1. Transmission mode: driven by helical gear

2. Printing color: 360 degree rotation

3. Adjustment method: Manual

4. The host adopts frequency converter to control speed

5. Printing plate: Resin offset plate

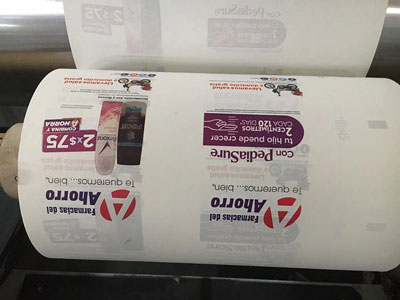

Samples