- Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

- Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

500MM Honeycomb Kraft Paper Roll Making Machine

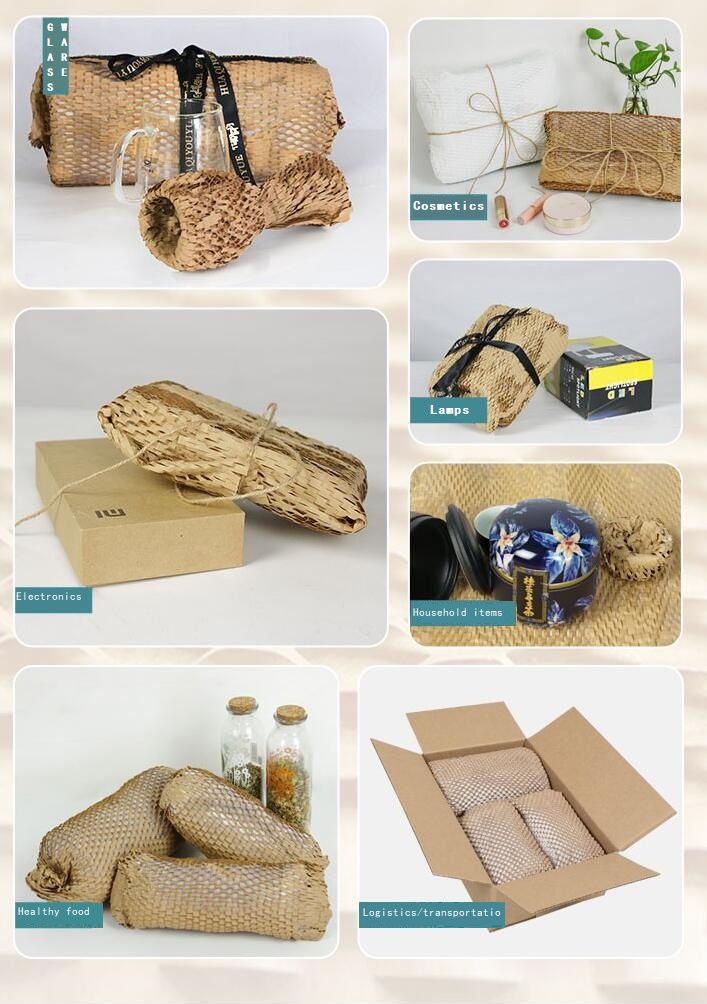

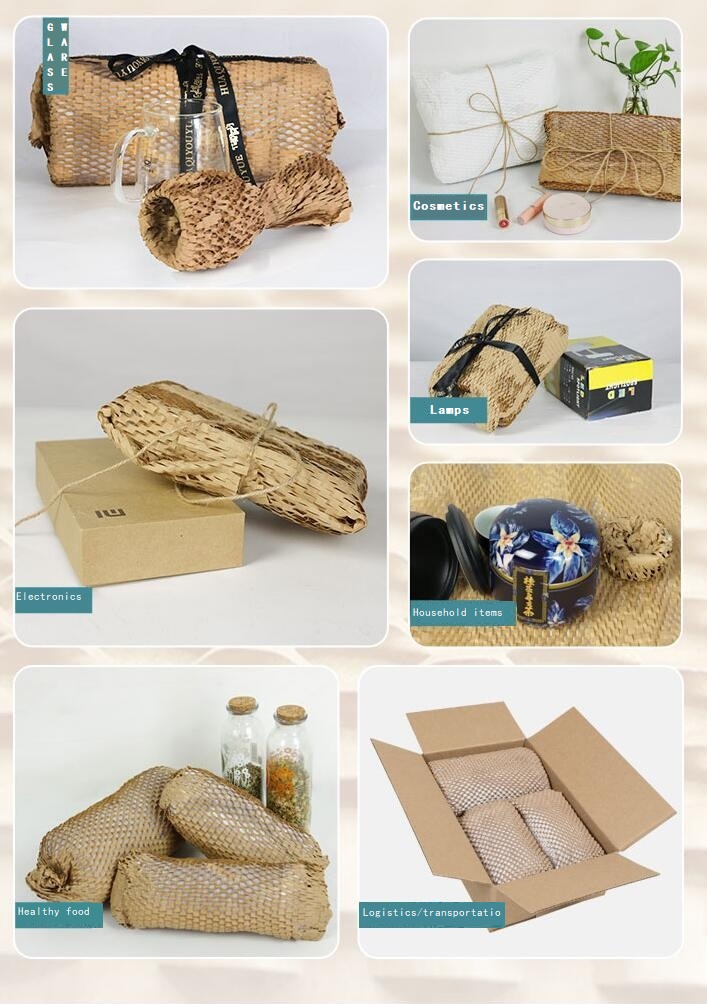

Products Description

.jpg)

Honeycomb paper is eco-friendly and cost effective alternative for plastic bubble wrap cushioning. It is easy to stretch,more soft and flexible,provide cushion protect without surface scratch. Finished products from this machine can be used to pack fruits,flowers,ceramics, glassware,etc.

Machine Advantages

1.This machine is suitable for die cutting honeycomb paper,wrapping paper, shock-absorbing paper, kraft paper,fish net paper from 70g to 100g.

2.The unwinding,cutting and rewinding in one process.

3.Main motor (Siemens brand) equipped with Inverter (Mitsubishi/Delta Brand) for speed regulation.

4. Computer with PLC (Mitsubishi/Delta brand) controlled, touch screen (Weinview brand).

5. Bearing NSK (Japan) brand,main machine body with thicker iron plate

6. Tension controlled automatically by magnetic powder brake and clutch,both is 20 kgs.

7. Automatic meter counting device,automatically stop after it reaches the length you set.

8. Pneumatic cylinder to control the cutting module up and down.

9. Automatic lifting system in unwinding and Web Guiding system

Machine Parameters

|

Machine model |

500 |

|

Max material width |

515mm |

|

Machine working speed |

0-150m/min |

|

Unwinding diameter |

Max. 1200mm |

|

Rewinding diameter |

Max. 300mm |

|

Unwinding roll weight |

Max. 1 T |

|

Unwinding shaft |

3” |

|

Rewinding shaft |

1”/1.5”/2”/3” |

|

Machine size |

1850*1350*1300mm (LxWxH) |

|

Machine weight |

1800 KG |

|

Machine power |

5 KW |

|

Power supply |

380V 3 Phase,50hz |

Details Images

.jpg)

-1011.jpg)

.jpg)