When choosing a paper box making machine for your business, several factors need to be considered, such as production capacity, product quality, functionality, cost, and after-sales service. Here are the details:

Production Capacity

-

Output Requirements: Evaluate your expected production volume. If you have a large number of orders, choose a machine with a high production speed and output, like models that can produce 500 to 1000 paper boxes per hour.

-

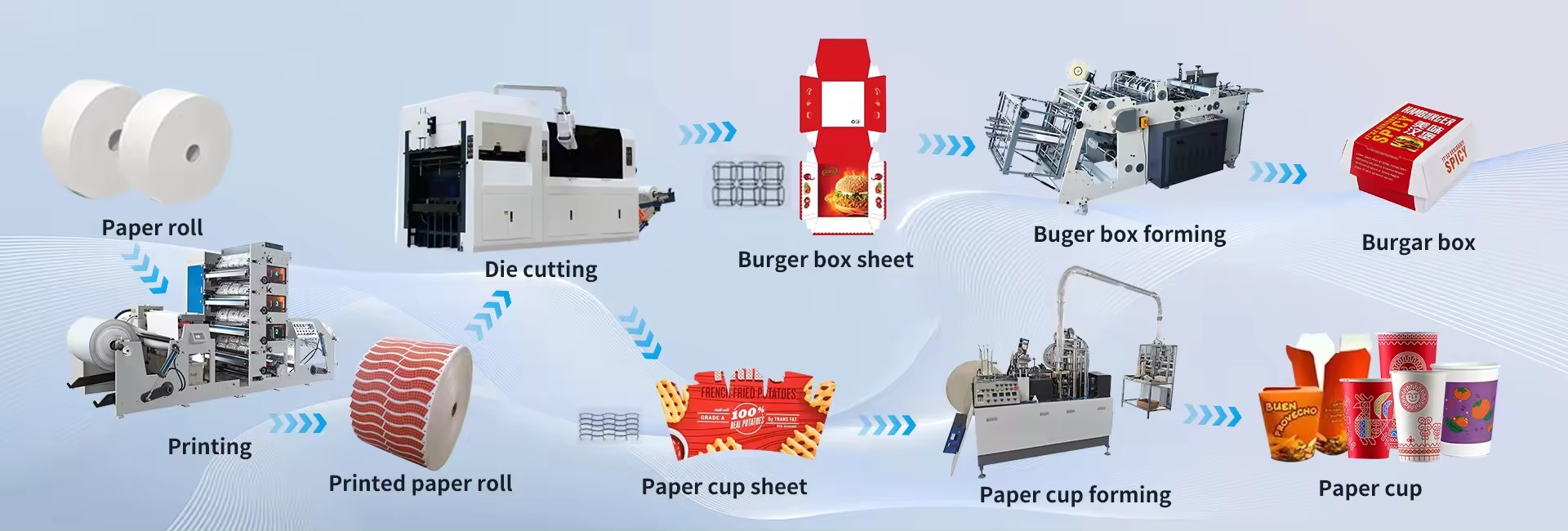

Production Efficiency: Consider the machine's operation speed, automation level, and the time needed for changeovers. Fully automatic machines with functions like automatic paper feeding and gluing can boost efficiency.

Product Quality

-

Printing Quality: If the paper box requires high-quality printing, ensure the machine can offer clear patterns, accurate color registration, and rich color expression. Flexographic and offset printing machines usually have good printing quality.

-

Forming Precision: The machine should be able to make boxes with precise dimensions and a neat appearance, with uniform folding and gluing, and no deformation or misalignment.

-

Material Compatibility: It should adapt to various paper materials, such as corrugated paper, cardboard, and coated paper, to meet different product requirements.

Functionality

-

Box Types: The machine should be able to make different box styles, like regular slotted cartons, half-slotted cartons, and special-shaped boxes. Some advanced machines can make complex structures through program settings.

-

Additional Functions: Optional functions like die-cutting, creasing, and window punching can increase the machine's versatility.

Cost

-

Purchase Cost: Set a reasonable budget and consider the machine's price and performance. Don't just focus on the initial purchase price but also consider its long-term value and return on investment.

-

Operating Costs: This includes energy consumption, maintenance costs, and labor costs. Machines with low energy consumption and easy maintenance will save costs in the long run.

Brand and After-sales Service

-

Brand Reputation: Choose machines from well-known brands with good reputations in the industry, as they usually offer more stable quality and better performance.

-

After-sales Service: Ensure the manufacturer provides good after-sales service, including equipment installation, training, maintenance, and spare parts supply. Timely technical support is crucial for solving problems during use.

Space Requirements

-

Machine Size: Measure the available space in your factory and choose a machine that fits the space without causing congestion, considering not only the machine's footprint but also the space needed for operation and maintenance.

-

Layout Compatibility: The machine should fit well with your existing production line layout to ensure smooth production flow.

Environmental Friendliness

-

Emissions and Pollution: Choose machines that meet environmental standards and have low emissions of waste gas, waste water, and noise. Some machines use water-based inks and energy-saving technologies, which are more environmentally friendly.

-

Waste Reduction: Consider machines that can reduce paper waste and improve material utilization, like those with precise cutting and feeding systems.

Xuanhai paper food box making machine is a special forming machine for producing takeaway food boxes of different specifications. It adopts high-quality sealed bearings and intelligent module temperature control, with fast response and short time, and the maximum speed can reach 300pcs/min.If you want to know more about paper box machine, please contact us.

- Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

- Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine