- Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

- Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

-

Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

Hospital Bouffant Cap Making Machine

Performance and characteristics

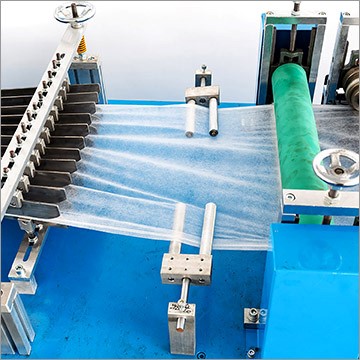

1. This machine can produce one-time dust-proof non-woven strip cap of non-woven material and plastic film material. It has the advantages of good quality, low price, high output, saving labor and reducing cost. It can be customized according to customers'requirements.

2. This machine is automatic. Automation of the whole process from feeding raw materials to layered products to product counting. Ultra-high power ultrasonic welding is used to fix both ends of non-woven fabric and rubber band effectively. From feeding raw materials to finished products, the whole process of automation, computer infinite speed regulation operation is more flexible, the whole process only needs one staff member.

3. Frequency conversion control speed regulation.

4. Disposal of finished products directly.

5. Automatic constant temperature control.

6. The combination of ultrasonic fusion welding and electrothermal bonding makes the product more comfortable and firm.

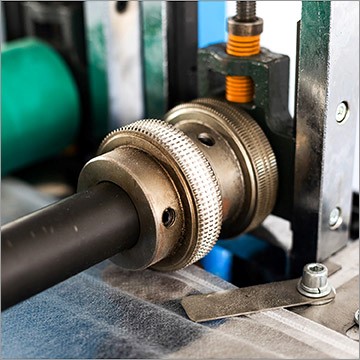

7. Major parts are made of aluminium to make the machine lighter and cleaner.

Equipment and technology

The equipment adopts ultrasonic heating mode, frequency conversion speed regulation, and produces one-off dust-proof non-woven fabric strip cap of non-woven material and PE plastic film material, which integrates the production from feeding material to finished product.

Production process

Automatic feeding-importing-folding-welding-forming cutting

Two choices

Our machine can produce two styles, one is iron frame and the other is aluminum frame. (PLC touch screen is optional)

sample and machine detail picture

|

|

|

|

|

|