- Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

-

Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

IML Intermittent / Full Rotary Label Die Cutting With Sheeting

Product Description

Intermittent/full rotary label die cutter, is a popular used machine for the in-mold label market, a cost-effective die-cutting solution for IML. This equipment is designed to solve the problems of label printing enterprises such as in-mold labels being unable to be die-cut or the use of traditional equipment being inefficient. This machine integrates the in-mold label full-rotation die-cutting method and the self-adhesive intermittent die-cutting method. The two working modes can be interchanged at will. Small batches of in-mold labels can also be cut in the intermittent mode. It well solves the confusion of printing factory's difficulty in starting the in-mold labeling project. Easily convert from intermittent to full rotation, providing a high quality solution for label materials. In addition, lamination, striping or cutting into sheets are also optional.

Main technical parameter

|

Model No. |

TP-330 |

|

Max Die Cutting Area |

350mm×290mm (L×W) |

|

Paper Width |

80mm---300mm |

|

Max Speed |

300RPM(65M/MIN) |

|

Accuracy of Cutting |

±0.1mm |

|

Max Unwinding Dia. |

φ700mm(about 2000Meters) |

|

Max Rewinding Dia. |

φ700mm(about 2000Meters) |

|

Magnetic Cylinder |

120Teeth 1/8 (Standard) |

|

Length of Die Cutting |

50mm~350mm |

|

MOTOR Power |

8 KW |

|

UV POWER(KW) |

Inkjet:4.8 Cold stamping:7.0 |

|

Overall Diameter(L×W×H) |

2900mm×1200mm×1500mm |

|

weight |

2500KG |

Standard configuration

A:Web guiding system.

B:Tension control system

C:120teeth/381mm magnetic cylinder.

D:Servo motors

E:HMI Touch screen operating system

F:Waste matrix mandrels.

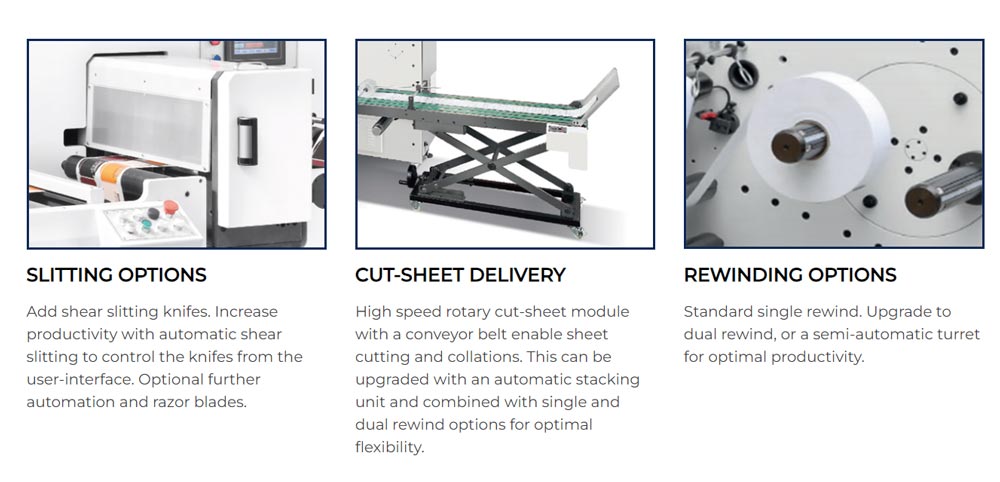

Optional Unit

A:Single Inkjet nozzle+UV:

(each one more nozzle charges _____USD/set)

B:Flexographic UV(with Cold stamping unit):

C:Laminating:

D:Rotary die cutting unit

E:Slitting unit:

F:Sheeting & paper collecting table:

rotary die cutting machine the latest products for the label converting and finishing process.Modular designs with many functions optional,Inkjet press,flexographic UV,Varnishing,Cold stamping,Die cutting,Slitting,Sheeting.etc.The machine shows great effort in humanity design and friendly operating.