Service Online:

Request a Quote

- Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

- Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

Twisted Handle Making And Pasting Machine

Product Description

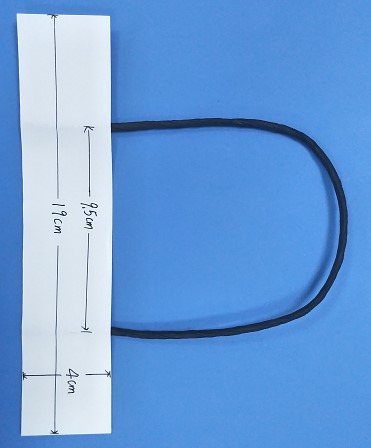

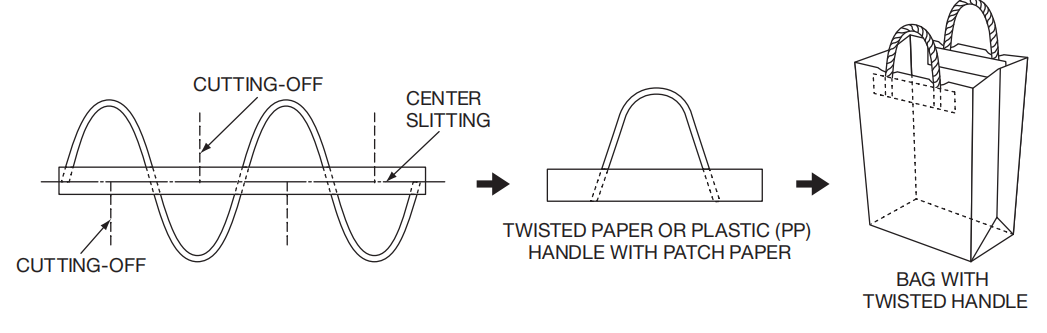

The paper twisted handle making and pasting machine use the twisted rope, paper rolls and the hot melt adhesive as raw material to produce the twisted handle and then paste the handle and paper bags together to get the shopping bags with twisted handle.It is support for square bottom paper bag machine to produce the bags with handle.Through the belt, paper roll and glue system to get the twisted handle, and then cut off them separately, and then paste the already made paper bags with the handle together,then the paper bags with handle are done.

Machine Parameter

| Handle length(A) | 152/190mm |

| Rope spacing(B) | 75/95mm |

| Paper width(C) | 30/40mm |

| Paper rope length | 360mm |

| Paper rope height(D) | 100mm |

| Rope diameter | Φ2.5~5mm |

| Bag width | 250-400mm |

| Bag length | 250-450mm |

| Top opening size | Over 130mm |

| Production speed | 30-35 pcs/min |

| Servo motor power | 750W |

| Total power | 380V,10KW,50HZ |

| Overall dimension | L6000*W1600*H1500mm |

| Handle length(A) | 152/190mm |

| Rope spacing(B) | 75/95mm |

| Paper width(C) | 30/40mm |

| Paper rope length | 360mm |

Machine Details

| 1. Using FLEXEM touch screen man-machine interface control system, operating at a glance. |

| 2. double unwinding unit |

| 3. use Arise EPC to ensure the handle patch on the right position |

| 4. high quality hot melt system can reduce the melt cost and defective |

| 5. top brand hot melt system made in taiwan durable and long service life |

| 6. feeder transmit paper bag automatically |

| 7. Taiwan made DELTA robotic arm durable and long service life |

| 8. Handle making unit |

| 9. Siemens servo driver and inverter |

| 10. Siemens |