-

Paper Food Box Making Machine

- Three-dimensional carton forming machine

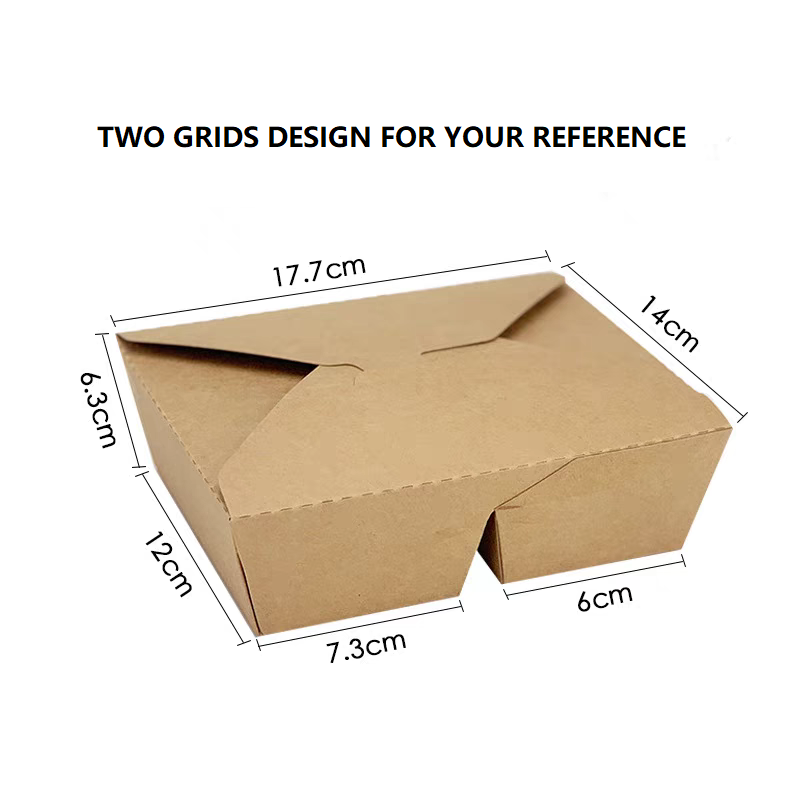

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

- Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

ZF-DG Multi Grid Take Away Kraft Paper Lunch Box Forming Machine

Introduction

1. Mechanical transmission, speed, energy-saving, stable and simple operation, microcomputer detection and domestic advanced technology products.

2. ZF-DG full automatic intelligent medium speed cake cup machine is automatic paper molding equipment, has the advantages of high speed, convenient operation etc.. This machine adopts built-in hot air generator, suitable for single PE coated paper.

3. For the production of single-cell disposable paper boxes, chinese paper take out boxes, takeaway paper containers,cupcakes, food packaging boxes,kraft takeaway food boxes,brown paper take out boxes and B automatic intelligent medium speed cake cup machine through the automatic feed paper, heating (comes with hot air generating device), hot press molding (adhesive box four corners), automatic points collected, microcomputer control of continuous processes.

4. The fastest working speed is 30 times per minute. It has the monitor computer system .If the fault the machine will stop and alarming

Technical Specification

|

Type |

ZF-DG |

|

Production capacity |

18-20pcs/min (Actual production is based on product size) |

|

Maximum size: |

200mm*270mm*45mm |

|

Suitable Material: |

200-600g/m2 PE Coated paper |

|

Total Power: |

7KW |

|

Total Weight: |

1.6T |

|

Machine Dimension: |

3400 x 1700 x 2600 mm |

|

Working Air Source: |

Air pressure 0.8Mpa (Need to buy compressor) |

Components Brand

|

Motor |

Main motor |

(CHINA SHANGHAI) |

|

SEVER MOTOR |

(CHINA HANGZHOU) |

|

|

Electrical equipment |

PLC |

(CHINA XIAMEN) |

|

TOUCH SCREEN |

(FLEXEM) |

|

|

TEMPERATURE CONTROL |

AUTONICS(KOREA) |

|

|

Relay |

(CHINT) |

|

|

Contactor |

(CHINT) |

|

|

Frequency converter |

(GTAKE) |

|

|

Photoelectric switch |

PANASONIC (JAPAN) |

|

|

Pneumatic |

Main cylinder |

AirTAC(TAIWAN) |

|

Other pneumatic components |

China famous brand |

|

|

other bearings |

HBR |