-

Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

- Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

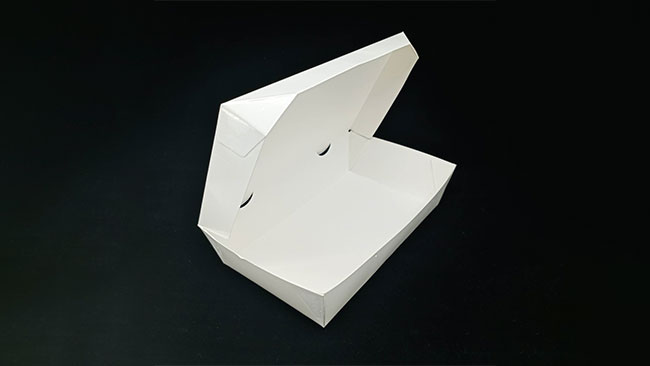

BC-CHJ-6C Kraft Paper Lunch Box Forming Machine

| Model | BC-CHJ-6C |

| Capacity | 18-23pcs/min |

| Suitable material | 200-400gsm (single & double PE Coated Paper) |

| Paper size | 150-320x250-370mm |

| Power supply | 380V/50HZ/3PH, 8KW |

| Air consumption | 0.8Mpa, 0.6m3/min |

| Machine size | 2250x1220x1950mm |

.jpg)

Product Description

1. Automatic paper lunch box machine: mechanical transmission, fast speed, energy saving, stable, simple operation, microcomputer detection, domestic advanced technology products.

2. Automatic paper lunch box machine is an automatic paper product forming equipment with the advantages of fast speed and easy operation. This model is equipped with a hot air generating device and is suitable for a single sheet of PE coated paper.

3. The automatic paper lunch box machine produces a single box through a continuous process such as automatic paper feeding, heating (with its own hot air generating device), hot pressing (gluing the four corners of the lunch box), and automatic positioning. Collection, microcomputer control. Disposable paper lunch boxes, paper lunch boxes, cake cups, food packaging boxes, etc.

4. The current maximum working speed of the equipment is 35 times/min. It has automatic systems such as feeding monitoring, paper feeding monitoring, forming monitoring, and paper delivery monitoring. If there is a fault, the machine will stop and beep.