- Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

- Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

8 Station CI Flexo Press

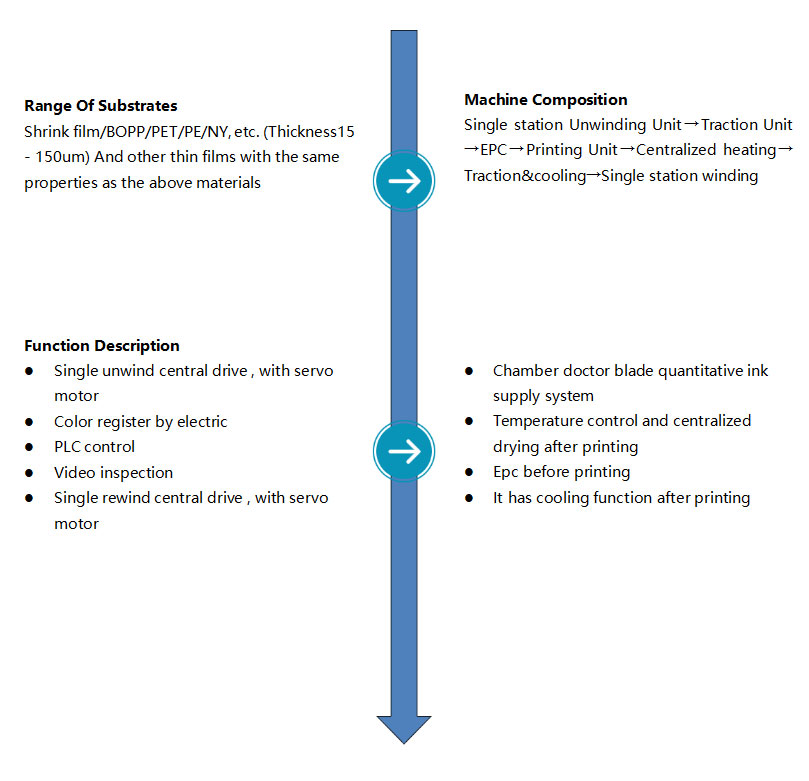

Instruction

Specifications

|

GENERAL SPECIFICATION |

|

|

Number of Printing Station |

8 |

|

Max. Web Width |

1200mm |

|

Max. Printing Width |

1150mm |

|

Printing Repeat |

400mm-800mm |

|

Max. Mechanical Speed |

300m/min |

|

Max. Printing Speed |

200-250m/min The effective printing speeds will depend on following printing conditions: - Type of material; - Repeat of printing cylinders; - Inks, lacquers and solvents; - Required printing quality; - Level of solvent retention. |

|

Register precision |

Longitude:±0.1mm ; Transverse:±0.1mm |

|

Plate thickness + Tape thickness |

1.7mm or to be specified |

|

Heat source |

Electrical elements |

|

Electrical supply |

3Phase, 380V, 50HZ or to be specified |

|

Ink |

water based ink or solvent ink |

|

Main Control |

PLC |

Substrates

Machine Details

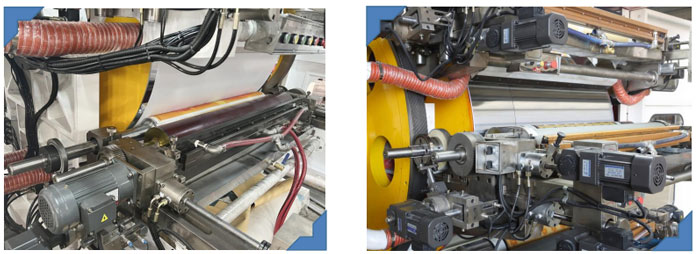

Single Unwind

Max.Roll diameter: Φ800mm

Single unwind central drive , with servo motor ,Inverter control Closed-loop.

Tension control : Adopt Light float roller . tension auto compensation ,close-loop control.

EPC (edge position control): Set and run four roll type automatically EPC ultrasonic detector system; With manually/automatically/ central return function, can adjust left and right around ±65mm width.

Automatic keep tension when machine stop; Avoid material loose

One air shaft 3”

Unwind web cylinder: Φ76mm (inner diameter)

Printing Unit

Vibration-free cast iron frame thickness 100mm.

Laser engraved ceramic coated anilox roller, 8 pcs, line count to be specified.

Anilox roller precision of dynamic balancing10g.

Automatic mixing the ink when halt machine, Prevent ink drying.

Locking print cylinders with hydraulic lift providing complete rigidity and vibration free running up to maximum speed.

Hydraulic positioning: When starting up, the hydraulic cylinder pushes the anilox roller close to the plate roller for inking, and the plate roller closes to the central roller for printing, locking, the hydraulic cylinder presses together for positioning printing.

When the machine is stopped, the locking cylinder automatically releases pressure, the hydraulic cylinder pushes the anilox roller away from the plate roller, and the plate roller leaves the center roller, but the gears are still meshed. Automatic reset when the machine is turned on again for printing, and the color registration/printing pressure will not change.

There is a sequence of time when the Anilox roller and the plate roller are retreated. Realize the self-cleaning function of the printing plate during shutdown, reduce the frequency of cleaning the plate, and improve the service life of the printing plate.

Online vertical and horizontal electric precise quantitative positioning and rapid plate registration, with automatic center return function, PLC control

The color registration accuracy will not change when the machine printing speed is increasing or decreasing

Denmark technology aluminum alloy Chamber doctor blade system with double cycle ink pump 8 sets

7 for 8 color between color drying modules

Overhead crane, easy to lift the materials, cylinders and rollers.

Central impression roller with Constant temperature water cooling system (industry chiller can be added as option )

Anti-wrinkle device with curved rollers before printing

Water cooling system for CI

PLC Control and Operation Panel

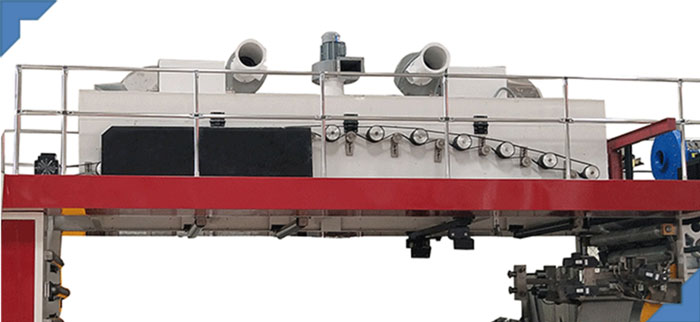

Heating & Drying Unit (proprietary technique)

Drying sysyem

- Hot air mode:Electrical heating, transformed into circulating air heating by heat exchanger. Temperature control adopts intelligent temperature control, contactless solid-state relay, set 2 control, suit to different technology、environment production, save energy consumption, enforce PID temperature control and temperature control precision,±2℃.

Dryer between each color

- Electrical heating, transformed into circulating air heating by heat exchanger. Temperature control adopts intelligent temperature control, non-contact solid-state relay, set 2 control, suit to different technology、environment production, save energy consumption, enforce PID temperature control and temperature control precision,±2℃.

- Dry box between each color has windleitung and return wind pipe.

- Stainless steel cover, aluminium alloy spray nozzle.

Drying oven structure

- Drying oven inner container.

- Heat exchanger.

- Muzzle are all made of stainless steel plate.

- Dry oven has independent fan for intake air and independent fan for air exhaust. By control the supply air rate and adjust air damper, the machine printing process will get the best wind speed、wind pressure, higher drying oven heat efficiency, and save energy consumption; Cylinder control the drying oven opening and closing, with guard bar and walkway floor.

Rewind Unit

|

Max. rewind diameter |

Φ800mm |

|

Rewind method |

One unit use center drive rewind,servo motor ,Inverter closed-loop control. |

|

Tension control |

adopt super light float roller, and tension automatic compensation, closed-loop control. |

|

Inspection light |

1 set |

|

Rewind material holder |

By air shaft 3’’, 1pcs |

|

Rewind web cylinder |

Φ76mm (inner diameter) |

|

Automatic stop machine when break the material; When machine stop, keep tension and avoid the material loose or line deflection. |

|